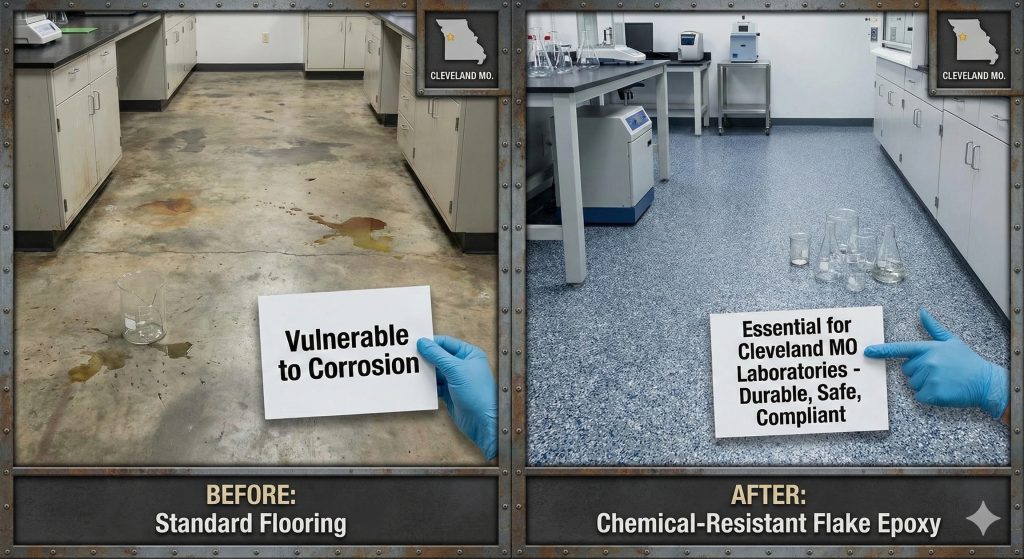

Laboratories—whether clinical, research, educational, or industrial—require flooring that can withstand constant use, harsh chemicals, strict sanitation, and demanding safety standards. For labs in Cleveland, MO, chemical-resistant flake epoxy flooring has become the preferred solution thanks to its unmatched durability, seamless design, and superior resistance to spills and contaminants.

At High Stakes Epoxy LLC, we install commercial-grade epoxy systems engineered specifically for environments where precision, cleanliness, and safety are critical. Here’s why chemical-resistant flake epoxy is not just an upgrade—but an essential flooring solution—for any laboratory in Cleveland, MO.

⭐ 1. Superior Chemical Resistance for Harsh Environments

Laboratories frequently work with:

- Acids

- Solvents

- Cleaning agents

- Alcohols

- Oils and lubricants

- Biological materials

Ordinary concrete or tile cannot withstand repeated exposure to these substances.

Chemical-resistant flake epoxy protects against:

- Surface etching

- Staining

- Corrosion

- Absorption of hazardous materials

- Long-term chemical degradation

This strong barrier ensures your floor remains intact—even after years of demanding use.

⭐ 2. Seamless, Non-Porous Surface for Sanitation and Cleanliness

Laboratories must adhere to strict hygiene standards. Seamlessly coated epoxy floors eliminate grout lines, joints, and pores where contaminants can hide.

Benefits include:

- Easier disinfection

- No bacteria or mold growth

- No cracks where spills can soak in

- Faster cleanup after experiments or procedures

A seamless flake epoxy floor helps labs maintain compliance with health and safety regulations.

⭐ 3. Slip-Resistant Texture for Employee Safety

Chemical spills, condensation, or water can make lab floors dangerous. The vinyl flake broadcast in epoxy adds texture that enhances traction without compromising cleanability.

Safety benefits:

- Reduces slip-and-fall accidents

- Improves stability when walking with equipment

- Works even in labs with frequent liquid exposure

A safer work environment protects employees and reduces liability.

⭐ 4. Exceptional Durability Under Heavy Use

Laboratories are high-traffic spaces, often filled with:

- Rolling carts

- Heavy machinery

- Storage racks

- Diagnostic equipment

- Cleaning routines

Chemical-resistant flake epoxy withstands:

- Abrasion

- Impact

- Heavy loads

- Continuous foot traffic

This makes it a long-lasting solution for labs that operate daily or around the clock.

⭐ 5. Moisture and Spill Protection

Lab floors regularly face spills—everything from water to corrosive chemicals. Flake epoxy creates a waterproof, non-absorbent surface that prevents moisture from penetrating the concrete.

This reduces risks of:

- Mold

- Bacterial growth

- Odors

- Structural slab damage

It also ensures spills can be cleaned quickly and safely.

⭐ 6. UV-Stable, Long-Lasting Finish

Many laboratory spaces use bright LED lights or natural light from windows. Without UV stability, traditional coatings may yellow or degrade.

Flake epoxy systems from High Stakes Epoxy LLC use polyaspartic topcoats, which are:

- UV-resistant

- Fade-proof

- Gloss-retaining

- Chemically protective

This ensures the floor maintains its professional appearance for years.

⭐ 7. Custom Color Blends to Define Zones and Improve Organization

Laboratories often require designated zones for:

- Hazardous materials

- Clean areas

- Equipment staging

- High-traffic walkways

- Emergency routes

Flake epoxy can be completely customized using:

- Unique color blends

- Solid color accents

- Defined borders

- Non-slip markers

This helps improve workflow, safety, and compliance with OSHA guidelines.

⭐ 8. Low Maintenance, Cost-Effective Long-Term Solution

Unlike tile, vinyl, or polished concrete, flake epoxy does not require:

- Waxing

- Polishing

- Frequent resealing

- Grout cleaning

- Replacement every few years

A simple mop or scrub restores its cleanliness. Over time, this reduces operational costs for Cleveland, MO laboratories.

⭐ Ideal for All Types of Laboratory Environments

Chemical-resistant flake epoxy is perfect for:

✔ Research laboratories

✔ Medical and diagnostic labs

✔ Pharmaceutical facilities

✔ Food testing labs

✔ Industrial R&D environments

✔ University and educational labs

✔ Chemical processing areas

✔ Biotech and clean rooms

Where safety and durability matter most, epoxy flooring delivers.

⭐ Why Cleveland, MO Labs Choose High Stakes Epoxy LLC

We specialize in commercial and industrial epoxy systems tailored to rigorous environments. With High Stakes Epoxy LLC, you get:

✔ Commercial chemical-resistant epoxy systems

✔ Proper concrete grinding and preparation

✔ Seamless full-broadcast flake application

✔ UV-stable polyaspartic topcoats

✔ Slip-resistant, hygienic, and compliant flooring

✔ Fast installation with minimal disruption

✔ Floors engineered for 10–20+ years of laboratory use

We help labs create safe, clean, and compliant workspaces.

⭐ Upgrade Your Laboratory with Chemical-Resistant Epoxy Flooring

If your lab in Cleveland, MO needs a durable, hygienic, and chemical-safe flooring system, flake epoxy is the top choice.

📞 Contact High Stakes Epoxy LLC today for a free laboratory flooring assessment!

Let’s build a high-performance floor engineered for science, safety, and success.